Funny Stories About Francis Cabot Lowell

The Lowell System was a labor production model invented by Francis Cabot Lowell in Massachusetts in the 19th century.

The system was designed so that every step of the manufacturing process was done under one roof and the work was performed by young adult women instead of children or young men.

The Lowell System, which is also sometimes called the Waltham-Lowell System, was first used in the Waltham and Lowell textile mills during the industrial revolution.

This model was so successful that Lowell's business associates expanded and opened numerous textile mills in Massachusetts using this model.

Why Did Lowell Invent the Lowell System?

According to the Life and Times of Francis Cabot Lowell by Chaim M. Rosenberg, Lowell wanted to create a manufacturing process that was more efficient and one that benefited from the morals, education and strong work ethic of New Englanders:

"Francis Cabot Lowell, wealthy from birth and sheltered from the roughness of life, believed that success comes to those who work hard and failure is a personal weakness. His vision of the American textile factory differed from what he saw in Great Britain. America did not have a domestic cotton textile industry but depended on cloth imported from Great Britain and India. The factory he planned to build near Boston would create new jobs rather than replace home spinners and weavers. Lowell had great faith in the people of New England as the source of his labor force and believed 'that the character of our population, educated, moral and enterprising could not fail to secure success.' His workers would be housed and fed by the company and remain employed only a few years rather than form a permanently downtrodden underclass."

How Did Lowell Get the Idea for the Lowell System?

Lowell got the idea to build textile mills during his trip to Britain in 1811. Britain was the birthplace of the Industrial Revolution and its many new textile mills inspired Lowell to build similar, but better, mills in the United States, according to the book Introduction of the Power Loom, and Origin of Lowell by Nathan Appleton:

"My connection to the Cotton Manufacture takes date from the year 1811, when I met my friend Mr. Francis C. Lowell, at Edinburgh, where he had been passing some time with his family. We had frequent conversations on the subject of the Cotton Manufacture, and he informed me that he had determined, before his return to America, to visit Manchester, for the purpose of obtaining all possible information on the subject, with a view to the introduction of the improved manufacture in the United States. I urged him to do so, and promised him my co-operation. He returned in 1813. He and Mr. Patrick T. Jackson, came to me one day on the Boston exchange, and stated that they had determined to establish a Cotton manufactory, that they had purchased in Waltham, (Bemis' paper mill,) and that they had obtained an act of incorporation, and Mr. Jackson had agreed to give up all other business and take the management of the concern."

During Lowell's trip to England, he toured the mills and memorized the design of the power looms. After returning to the U.S., he formed the Boston Manufacturing Company in 1813 and the company built its first mill next to the Charles River in Waltham, Mass in 1814.

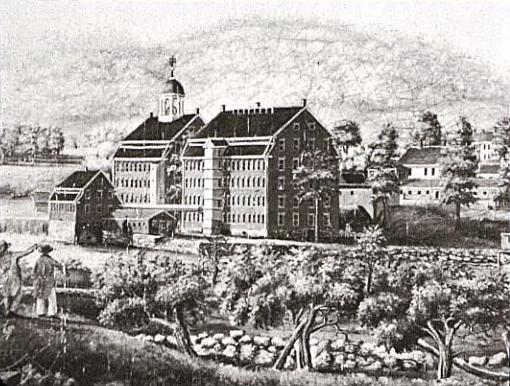

Boston Manufacturing Company, 1813-1816, Waltham, Ma, engraving by Elijah Smith circa 19th century

The Waltham mill was the first mill in the United States that could process raw cotton into finished cloth in one process and all under one roof with the help of its water-driven power loom, which is an apparatus used to weave yarn or thread into finished cloth.

Up until the time of the Industrial Revolution, looms were powered by a person via a foot pedal but the power loom was mechanized and powered by a line shaft driven by a source of running water, such as a river, which sped up the weaving process significantly. As a result, the power loom is considered one of the most important inventions of the industrial revolution.

The Lowell System was different from other textile manufacturing systems in the country at the time, such as the Rhode Island System which instead spun the cotton in the factory and then farmed the spun cotton out to local women weavers who produced the finished cloth themselves. Compared to these other textile mills, the Lowell system was unprecedented and revolutionary for its time, according to the book Life and times of Francis Cabot Lowell:

"Francis Cabot Lowell was hardly alone in his efforts to build a cotton textile industry in America. His system, however, differed markedly from Philadelphia homespun or the craft-factory model used in Rhode Island. Lowell's industrial order 'came to dominate the cotton industry [and] marked a radical departure from all that had gone before. In his 1864 book, Samuel Batchedler contrasts Francis Cabot Lowell's system with Samuel Slater's Rhode Island system. Slater ran small spinning mills, using copies of the English machinery, while Lowell developed new machines for his large factory and did spinning and weaving under power all under one roof. Slater used the labor of local families while Lowell employed healthy young women, housed and fed at the company's expense and paid wages in cash. Slater adhered to the old craft system while Lowell built labor-saving machines that required only a few weeks of training to master the repetitive tasks. Slater built small mills with a small number of spindles, while the mill at Waltham contained thousands of spindles and several looms watched over by hundreds of workers. The conservative Slater clung to his tried-and-true methods of production while Lowell leaped ahead with his modern factory using the machines of mass production. At Lowell's mill raw cotton came in at one end and finished cloth left at the other."

This Lowell System was faster and more efficient and completely revolutionized the textile industry. It eventually became the model for other manufacturing industries in the country.

The Lowell Mill Girls:

One of the problems Lowell faced in setting up his factory was finding workers. At the time, America was an agricultural society and many Americans were hesitant to work in a factory, according to the book Encyclopedia of the Industrial Revolution:

"Another problem the Waltham [Lowell] System was able to solve was the problem of labor. While European factories relied upon large, landless, urban populations whose reliance on the wage system gave them few economic choices, land was readily available to most Americans who desired it. As a result, Americans were generally unwilling to work in factory conditions, preferring instead the economic independence of agricultural labor. Many Americans, in fact, saw the European factory system as inherently corrupt and abusive. Additionally, since the American population was small, hired labor was expensive. In order to address this problem, Lowell designed a new business strategy to attract labor. As mill machinery greatly reduced the need for excessive human strength, Lowell did not necessarily need workers who were physically strong, but instead needed workers that could be hired cheaply. Lowell found his employees in the girls and young women of the surrounding countryside. These young women had experience in weaving and spinning from home manufacturing and worked for cheaper wages than did male employees."

The Lowell system created a new way to control the labor supply. The mill hired young, single women, between the ages of 15 and 35.

In order to persuade young women to leave their farms and small towns to work at the mills, Lowell created a factory community by building boardinghouses that were run by chaperones who enforced strict moral codes and he also made attendance of religious services mandatory, according to the book The Encyclopedia of the War of 1812: A Political, Social, and Military History:

"The Lowell System required hiring of young (usually single) women between the ages of 15 and 35. Single women were chosen because they could be paid less than men, thus increasing corporate profits, and because they could be more easily controlled then men. These mill girls, as they were called, were required to live in company-owned dormitories adjacent to the mill and were expected to adhere to the rather strict moral code of conduct espoused by Lowell. They were supervised by older women, called matrons, and were expected to work diligently and attend church and educational classes. The young women would work a grueling 80-hour work week. Lowell believed his system alleviated the deplorable working conditions he witnessed in England and helped him to keep a tight rein on his employees. By doing so, he cultivated employee loyalty, kept wages low, and assured his stockholders accelerating profits. Although Lowell's labor arrangement was highly discriminatory and paternalistic compared to modern standards, it was seen as revolutionary in its day. A large number of young mill girls went on to become librarians, teachers, social workers, etc., thanks in large part to the education they received while working at the mill; thus, the system did produce benefits for the workers and the larger society."

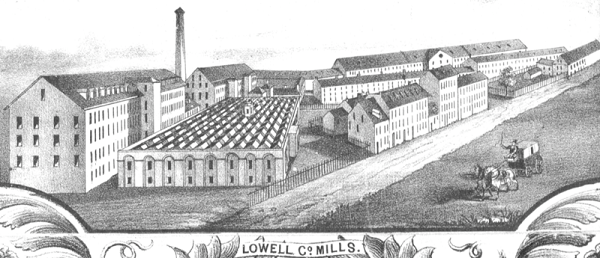

Plan of the city of Lowell, Massachusetts, illustration by Sidney and Neff, circa 1850

The Lowell System was not only more efficient but was also designed to minimize the dehumanizing effects of industrial labor by paying in cash, hiring young adults instead of children, offering employment for only a few years and by providing educational opportunities to help workers move on to better jobs, such as school teachers, nurses and etc.

Other mills during the industrial revolution, particularly in England, as well as the mills in Rhode Island, tended to hire poor, uneducated landless workers and children who had no other options than to work permanent low-paying jobs in the mills in dangerous working conditions with no opportunities for advancement, according to the book The Encyclopedia of the War Of 1812: A Political, Social, and Military:

"The Lowell System stood in sharp contrast to the prevailing system of textile manufacturing at the time, which was based on Samuel Slater's Rhode Island System. That system was established at a cotton-spinning mill near Pawtucket, Rhode Island, in 1790. Slater had employed young girls (7-12), who were exploited and often abused…Slater kept tight reins on his labor pool as well, but the young girls were harder to train and control than adult women."

Another source, a book titled The Story of Textiles: A Bird's Eye View of the History of the Beginning and the Growth of the Industry By Which Mankind is Clothed, points out how exploitative the English system and the Rhode Island system was compared to the Lowell system:

"Besides this difference in machinery there was a striking divergence in the method of treating the employees. In Slater's mills, which set the pattern for Rhode Island, the English plan for employing whole families, including children who were very young, was adopted, and it led to the bringing of families into the industrial centres that were wholly dependent upon the mills and that suffered severely when there was no work. Payments, too, were made in goods supplied at a factory store instead of the cash method followed at Waltham. At Waltham, wages were paid every week or two weeks, and boarding-houses in charge of a matron were provided for the employees, the conditions of which precluded the work of children or mitigated against the employment of whole families."

The Lowell mill girls were also encouraged to educate themselves and pursue intellectual activities. They attended free lectures by Ralph Waldo Emerson and John Quincy Adams at the company-owned Lowell Lyceum, circulating libraries provided access to books, and they were encouraged to join "improvement circles" which promoted creative writing and public discussion.

The work days were long though and many of the women found that they were exhausted at the end of the day, both mentally and physically, and could barely stay awake during the lectures, as one former Lowell mill girl wrote:

"After one has worked from ten to fourteen hours at manual labor, it is impossible to study History, Philosophy, or Science. I well remember the chagrin I often felt when attending lectures, to find myself unable to keep awake…I am sure few possessed a more ardent desire for knowledge than I did, but such was the effect of the long hour system, that my chief delight was, after the evening meal, to place my aching feet in an easy position, and read a novel."

A typical work day in the Lowell System lasted about twelve hours, depending on the season. The exact hours the employees worked changed per season. From May to August, the work day started at 5am. From September 1 to April, the work day started at dawn. From November to February, breakfast was served before work.

In March, breakfast was served at 7:15 am, from April to September it was served at 7am sharp and from September to October it was served at 7:30 am. Lunch was served throughout the year at 12:30pm.

From May to August, the work day ended at 7pm, in September it ended at dark, from October to March it ended at 7:30pm and in April it ended at dark.

After dinner, the employees attended lectures, formed groups aimed at self-improvement and attended church. Curfew was at 10pm. The Lowell employees worked six days a week and attended Church services on Sunday.

Mills on the Merrimack River, Lowell, Mass, circa 1908

The End of the Lowell System:

Overproduction during the 1830s caused the price of finished cloth to drop. In response, the mills cut wages and increased work duties, forcing the workers to work harder at a faster pace.

New management took over and the mills soon began to change, according to the book The Simple Life: Plain Living and High Thinking in American Culture:

"By the mid-1840s a new generation of mill managers was in charge, and their outlook differed considerably from the founding group. Profits rather than people seemed their primary, even sole, concern. As one of the new managers admitted, 'I regard my work people just as I regard my machinery.' Absent from his perspective was any sense of paternal responsibility for the moral and intellectual elevation of his operatives. 'So long as they can do my work for what I choose to pay them I keep them, getting out of them all I can.' This was not the enlightened industrial republicanism that Jefferson had envisioned and described; rather it was the cynical materialism that Charles Dickens saw at work in England at the time. Visitors to Lowell in the 1830s and 1840s repeatedly noticed the mills' growing similarity to the feared English system and also the discrepancy between the original Lowell ideal and its second-generation reality."

In 1834, the mill cut the workers wages by 25 percent. The mill girls responded by staging a strike and organizing a labor union called the Factory Girls Association. The union's efforts were unsuccessful. Two years later, the mill girls went on strike again when their housing rates were increased but the strike failed again.

Conditions continued to deteriorate until 1845 when the mill girls formed the Female Labor Reform Association. This association joined forces with other Massachusetts laborers to force the government to pass legislation aimed at improving working conditions in the state. The association helped pass laws the limited working hours but the mills simply ignored the new laws.

The Lowell system continued to fail when Irish immigrants, who started to flock to Massachusetts in 1846 to escape the famine in Ireland, sought work in the mills. These immigrant workers, who were mostly women with large families who often put their children to work in the mills with them, were willing to work longer hours for cheaper wages. Because these workers tended to be married and have families, they didn't live in the inexpensive company dormitories and instead lived in tenement housing.

This reliance on immigrant workers slowly turned the mills into what they were trying to avoid: a system that exploited the lower classes and made them permanently dependent on the low-paying mill jobs.

By the 1850s, the Lowell system was considered a failed experiment and the mills began using more and more immigrant and child labor.

Textile manufacturing in New England started to decline in the 1890s when new technological advances made it easier and cheaper to manufacture textiles in the south, where cotton was grown locally, heating costs were cheaper and there were fewer labor unions.

The mill's owners decided not to modernize or update the Massachusetts textile mills and instead invested in building modern textile mills in the south.

As a result, by the mid 20th century, all of the New England textile mills, including the Lowell textile mills, had either closed or relocated to the south.

To learn more about the industrial revolution, check out my article on the Best Books About the Industrial Revolution.

Sources:

Walton, Perry. The Story of Textiles: A Bird's Eye View of the History of the Beginning and Growth of the Industry, By Which Mankind is Clothed. John S. Lawrence, 1912.

Shi, David E. The Simple Life: Plain Living and High Thinking in American Culture. University of Georgia Press, 1985.

Bates, Christopher G. The Early Republic and Antebellum America: An Encyclopedia of Social, Political, Cultural and Economic History. Routledge, 2010.

The Encyclopedia Of the War Of 1812: A Political, Social, and Military History. Edited by Spencer C. Tucker, ABC-CLIO, 2012.

Appleton. Nathan. Introduction of the Power Loom, and Origin of Lowell. B.H. Penhallow, 1858.

Rosenberg, Chaim M. The Life and Times of Francis Cabot Lowell, 1775–1817. Lexington Books, 2011.

" Lowell and Lawrence Textile Mills." Harvard University Library Open Collections Program, ocp.hul.harvard.edu/ww/mills.html

"Lowell Mill Girls and the Factory System, 1840." The Gilder Lehrman Institute of American History, www.gilderlehrman.org/history-by-era/age-jackson/resources/lowell-mill-girls-and-factory-system-1840

"The Waltham Lowell System." National Park Service, www.nps.gov/lowe/learn/photosmultimedia/waltham_lowell.htm

Source: https://historyofmassachusetts.org/lowell-mills-factory-system/

0 Response to "Funny Stories About Francis Cabot Lowell"

Post a Comment